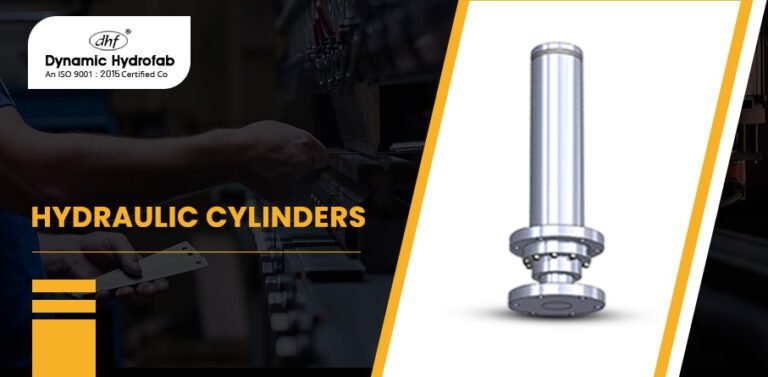

In the realm of industrial engineering, the efficiency and safety of fluid control systems depend heavily on the quality and performance of the valves used. One of the most trusted names in valve manufacturing is AUDCO Valves. Known for their reliability, durability, and performance across a wide range of industrial applications, AUDCO Valves are a preferred choice in industries such as oil and gas, petrochemicals, power, water treatment, and pharmaceuticals.

In this blog, we will explore the types of AUDCO Valves available and delve into their specific uses in industrial systems.

Why Choose AUDCO Valves?

Before diving into the types, it’s essential to understand why AUDCO Valves stand out in the market. As part of the L&T group, AUDCO has built a reputation for engineering excellence, strict quality control, and compliance with international standards. Their valves are designed to handle high-pressure and high-temperature conditions, making them ideal for critical industrial applications.

1. AUDCO Gate Valves

Overview:

Gate valves are primarily designed to start or stop the flow of liquid. When the valve is open, the gate is lifted out of the flow path, allowing unobstructed flow. When closed, it blocks the flow entirely.

Key Features:

- Full bore design

- Minimal pressure drop

- Suitable for bi-directional flow

- Available in a wide range of sizes and materials

Industrial Uses:

- Oil & Gas Pipelines: To isolate sections of a pipeline

- Power Plants: For high-pressure steam systems

- Water Treatment Facilities: For main inlet or outlet control

AUDCO Gate Valves are particularly popular in applications where a straight-line flow of fluid and minimum restriction is desired.

2. AUDCO Globe Valves

Overview:

Globe valves are used for throttling and regulating flow. They provide better control compared to gate valves due to their design, which allows precise regulation.

Key Features:

- Excellent throttling capabilities

- Good shut-off characteristics

- Suitable for high-pressure systems

Industrial Uses:

- Chemical Plants: For dosing chemicals accurately

- Pharmaceuticals: In clean environments requiring precise control

- Steam Systems: For regulating flow in heating systems

When precision and flow regulation are needed, AUDCO Globe Valves are the go-to solution.

3. AUDCO Ball Valves

Overview:

Ball valves use a spherical disc (ball) to control flow. They are quick to operate, reliable, and offer a tight seal, making them suitable for critical shut-off applications.

Key Features:

- 90-degree turn operation

- Low torque requirement

- Leak-proof sealing

- Available in full or reduced bore

Industrial Uses:

- Natural Gas Processing: For shut-off and isolation

- Water Supply Systems: Where fast shut-off is needed

- Food & Beverage Industry: Due to their sanitary design options

AUDCO Ball Valves are widely appreciated for their simplicity and effectiveness in high-cycle applications.

4. AUDCO Butterfly Valves

Overview:

Butterfly valves are quarter-turn valves ideal for large volume water or gas flow control. They consist of a disc that rotates to open or close the flow path.

Key Features:

- Compact and lightweight design

- Easy installation and maintenance

- Suitable for large pipe diameters

Industrial Uses:

- HVAC Systems: For regulating airflow

- Fire Protection Systems: For fast shut-off

- Water Treatment Plants: For flow isolation and regulation

For systems where space is limited but control is crucial, AUDCO Butterfly Valves offer an excellent solution.

5. AUDCO Plug Valves

Overview:

Plug valves use a cylindrical or tapered plug to control flow. They are simple in design and offer fast operation, making them ideal for frequent use.

Key Features:

- Quick quarter-turn operation

- Minimal flow resistance

- Available in lubricated and non-lubricated types

Industrial Uses:

- Oil Fields: For slurry and abrasive fluids

- Chemical Processing: For handling corrosive chemicals

- Gas Distribution: Due to tight sealing properties

AUDCO Plug Valves are especially useful in systems that require tight shut-off with frequent operation.

6. AUDCO Check Valves

Overview:

Check valves are non-return valves that allow fluid to flow in only one direction, preventing backflow that could damage equipment.

Key Features:

- Simple design

- No manual operation needed

- Available in swing, lift, and dual-plate designs

Industrial Uses:

- Pumping Stations: To avoid backflow when pumps are off

- Boiler Feed Systems: To protect against reverse flow

- Wastewater Management: For maintaining unidirectional flow

With AUDCO Check Valves, industries can ensure system integrity and reduce the risk of damage due to reverse flow.

Conclusion

The wide range of AUDCO Valves—from gate to globe, ball to butterfly, plug to check valves—demonstrates the brand’s versatility and reliability in industrial applications. Each valve type serves a distinct purpose, and choosing the right one depends on your system’s requirements for pressure, temperature, media type, and control needs.

Whether you’re managing a high-pressure steam line in a power plant or a chemical feed system in a manufacturing unit, there’s an AUDCO Valve designed specifically for your application. With their robust engineering and commitment to quality, AUDCO Valves continue to be a benchmark in the valve manufacturing industry.

Looking to source high-quality AUDCO Valves for your industrial system? Make sure you consult with an experienced distributor or engineering consultant to ensure you get the perfect valve for your needs.