Workplace safety is a significant responsibility in many businesses, particularly those that handle hazardous products, dust, and debris. A vacuum recovery system is an important instrument that helps to keep the workplace safe. These systems contribute to the reduction of risks associated with hazardous substance exposure, the improvement of air quality, and the enforcement of safety standards. In this blog, we’ll look at how vacuum recovery improves workplace safety, including its primary benefits and applications.

1. Elimination of Dust and Airborne Contaminants

Exposure to dust and airborne particles is a major safety problem in industries including construction, manufacturing, and mining. Fine dust, such as silica dust from cutting or grinding processes, can offer serious health risks, including respiratory disorders like silicosis. Vacuum recovery systems capture and remove dust at its source, limiting exposure to hazardous particles in the air.

Traditional dust collection procedures, such as sweeping or manual cleaning, frequently produce airborne dust clouds, increasing the risk of respiratory dangers. Vacuum recovery systems use intense suction to capture dust and particles at their source, keeping them from becoming airborne. This assures cleaner air, reduces respiratory hazards, and protects employees from long-term health issues.

2. Reduction of Exposure to Hazardous Materials

Certain sectors, such as chemical processing, waste management, and hazardous material cleaning, frequently involve the handling of poisonous compounds. Hazardous materials such as chemicals, oils, and solvents can cause severe skin irritation, breathing problems, and chemical burns. Vacuum recovery systems are vital for properly collecting and removing hazardous pollutants, lowering the danger of worker exposure.

Vacuum recovery systems, for example, are commonly utilized in situations prone to hazardous material spills or leaks. Workers are less likely to come into touch with hazardous chemicals if these items are extracted and contained rapidly, lowering the risk of accidents and injuries.

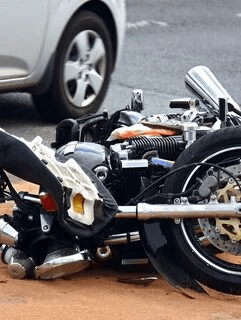

3. Prevention of Slips, Trips, and Falls

The accumulation of waste, dirt, and liquids in workplaces can create dangerous conditions such as slips, trips, and falls. Spilled liquids or loose materials in industrial environments can cause unstable surfaces, posing serious safety hazards to workers. Vacuum recovery systems help to reduce these hazards by efficiently removing dirt, liquids, and solid items from floors and work surfaces.

Vacuum recovery systems reduce workers’ exposure to slippery or uneven surfaces by keeping workstations clean and uncluttered. This leads to a safer working environment, particularly on construction sites, industrial plants, and warehouses, where such threats are common.

4. Enhanced Fire Safety

Vacuum recovery systems are also essential in industries where flammable materials are handled, such as oil refineries, paint booths, and facilities involving combustible dust. Accumulations of flammable dust or debris pose significant fire risks. A spark or ignition source near these materials can lead to catastrophic fires.

Vacuum recovery systems equipped with explosion-proof designs are designed to mitigate these risks. They prevent the accumulation of flammable dust, keeping work environments safer and reducing the likelihood of fire incidents. Regularly cleaning and removing combustible materials using vacuum recovery systems ensures compliance with fire safety regulations.

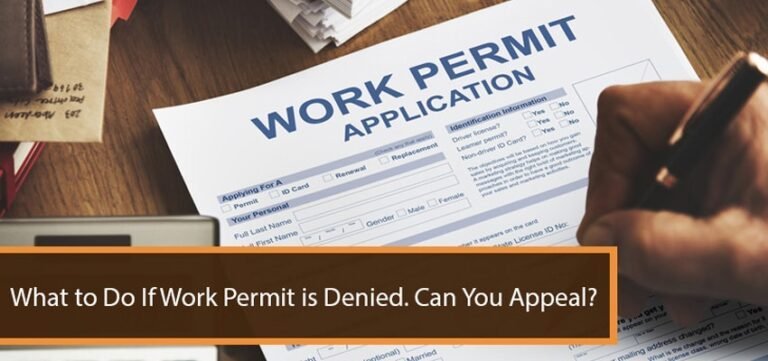

5. Compliance with Occupational Safety and Health Regulations

Workplaces are subject to numerous occupational health and safety rules, which require firms to reduce workplace dangers. Failure to follow these regulations can result in significant fines, legal liabilities, and reputational harm. Vacuum recovery systems assist enterprises in meeting these safety standards by efficiently managing hazardous materials, dust, and debris.

For example, the US Occupational Safety and Health Administration (OSHA) requires precautions to limit silica dust exposure. Vacuum recovery systems can be used to catch silica dust at its source, allowing enterprises to remain compliant with such laws. Other safety criteria, such as those governing hazardous waste or confined spaces, can be met by deploying vacuum recovery systems.

6. Improved Worker Morale and Productivity

A clean and safe workplace helps to boost employee morale and productivity. Workers feel more confident and comfortable in their work environment when they know that safety precautions are in place. Vacuum recovery systems help to provide a cleaner, healthier work environment, which reduces employee absenteeism due to illness or injury.

When employees are not concerned about dust-related health risks, hazardous material exposure, or unsafe working conditions, they are more likely to focus on their tasks, increasing productivity. The existence of vacuum recovery systems promotes a safe culture by encouraging staff to follow safety regulations and best practices.

7. Sustainability and Environmental Benefits

Vacuum recovery systems not only improve worker safety, but they also encourage sustainability by reducing waste and lowering environmental effect. By efficiently collecting and disposing of dust, debris, and hazardous materials, these systems decrease the need for manual cleanup methods, which can cause more waste. This results in a more effective and environmentally responsible approach to workplace safety.

Furthermore, vacuum recovery systems help to conserve resources by making better use of cleaning materials and lowering the number of cleaning procedures. This lowers the overall environmental impact, making the workplace safer for both people and the world.

Summary

Vacuum recovery systems are critical instruments for improving worker safety across a variety of industries. These systems make workplaces safer for employees by minimizing dust, reducing exposure to hazardous materials, preventing slips and falls, enhancing fire safety, and guaranteeing compliance with safety requirements. Furthermore, using vacuum recovery systems improves employee morale, productivity, and sustainability, all of which contribute to a healthier and safer workplace. Investing in vacuum recovery systems is a proactive way to protect workers and create a safer working environment.