The dry mix mortar industry has evolved significantly over the years, and as we look toward 2025, several key trends are emerging that will shape the future of dry mix mortar plant suppliers. These trends not only reflect technological advancements but also underscore the growing importance of sustainability, efficiency, and quality in the construction sector. As more businesses realize the benefits of dry mix mortar, the role of suppliers becomes increasingly vital in meeting the demands of the global construction market.

1. Sustainability and Eco-Friendly Solutions

One of the most significant trends impacting dry mix mortar plant suppliers in 2025 is the increasing focus on sustainability. As environmental regulations tighten and the construction industry shifts towards greener practices, dry mix mortar plant suppliers must adapt to meet the growing demand for eco-friendly products. Manufacturers are investing in renewable energy sources, recycling initiatives, and eco-conscious production methods.

In addition to using more sustainable materials, suppliers are also focusing on reducing their carbon footprint during production. Dry mix mortar plant formulations are being enhanced to include recycled aggregates, waste materials, and low-carbon alternatives. This trend not only addresses environmental concerns but also provides construction companies with more cost-effective solutions that align with their sustainability goals.

2. Automation and Smart Technologies

As automation continues to transform industries globally, dry mix mortar plant suppliers are increasingly incorporating smart technologies into their operations. Automation enhances plant efficiency, reduces human error, and improves overall product quality. With 2025 on the horizon, we expect dry mix mortar plants to become more automated, with advanced control systems, robotic handling, and even AI-powered monitoring systems to optimize the production process.

Furthermore, smart technologies such as sensors and IoT (Internet of Things) devices will allow plant operators to monitor and manage production in real-time. These technologies will help improve supply chain management, ensure consistent product quality, and streamline plant operations, ultimately leading to faster delivery times and higher customer satisfaction.

3. Customization and Tailored Solutions

As construction projects become more diverse and specialized, the need for customized dry mix mortar solutions will continue to grow. Dry mix mortar plant suppliers are responding by offering more tailored products that meet the unique needs of different construction applications. Whether it’s for residential, commercial, or industrial projects, suppliers are creating specific formulations that enhance performance, durability, and ease of use.

For example, some suppliers are developing high-performance dry mix mortars for specialized applications such as high-rise buildings, bridges, and roads, while others are focusing on environmentally friendly products suitable for green construction. This trend of customization ensures that construction projects receive the exact product they need to perform optimally, making dry mix mortar plant suppliers integral partners in the success of modern construction.

4. Digitalization and Supply Chain Optimization

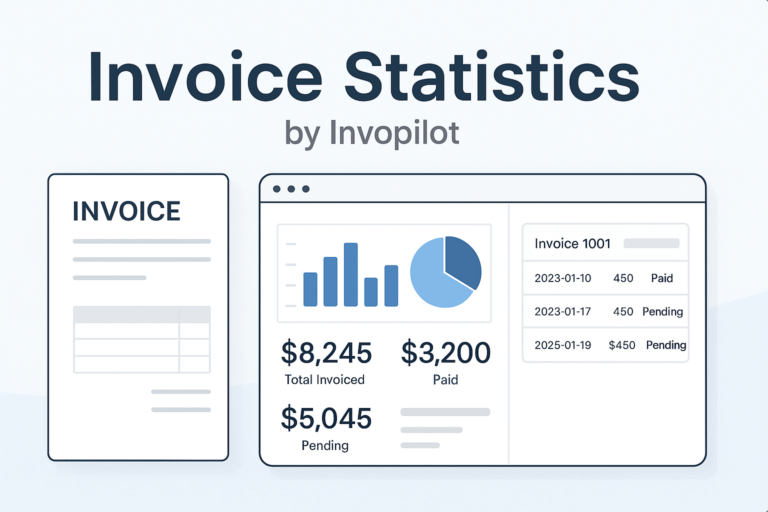

Digitalization is revolutionizing the way dry mix mortar plant suppliers interact with clients, manage inventory, and track deliveries. In 2025, we expect even greater integration of digital platforms that will allow suppliers to offer seamless online ordering, real-time tracking, and transparent communication with clients. These digital tools will not only enhance the customer experience but also help suppliers optimize their operations.

Additionally, supply chain optimization through digital technologies will help dry mix mortar suppliers stay ahead of demand, reduce lead times, and manage resources more efficiently. Real-time inventory management systems and data analytics will ensure that suppliers can maintain product availability while reducing waste and production costs.

Conclusion

The dry mix mortar industry is undergoing rapid transformation, and the key trends shaping the market in 2025 highlight the industry’s move toward sustainability, automation, customization, and digitalization. For construction companies looking for reliable and innovative dry mix mortar plant suppliers, it is essential to partner with those who are at the forefront of these advancements.

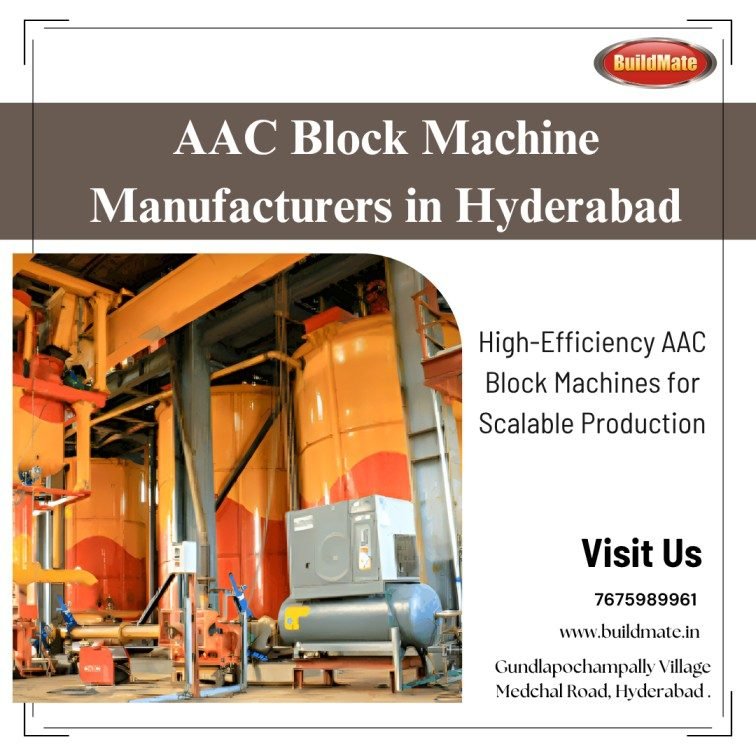

Buildmate, a leading dry mix mortar plant supplier, is committed to staying ahead of industry trends and providing high-quality, eco-friendly, and cost-effective solutions to meet the evolving needs of the construction sector. With a focus on innovation and customer satisfaction, Buildmate is well-positioned to lead the way as the dry mix mortar market continues to grow and transform in 2025 and beyond.