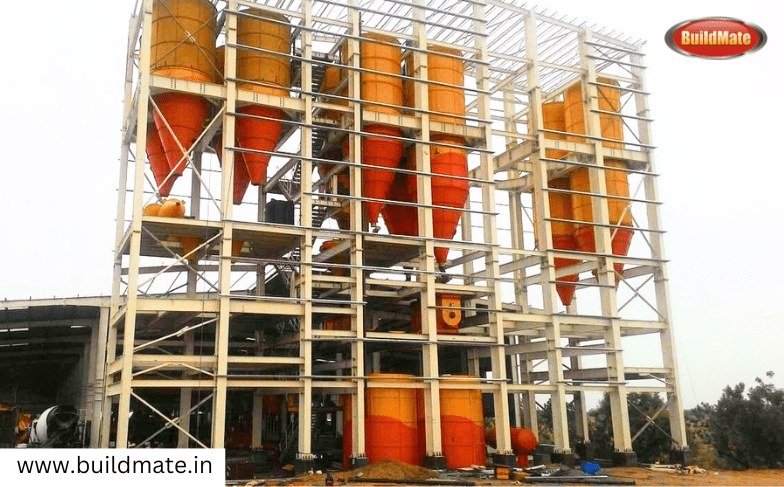

The construction industry is rapidly evolving, with new technologies and innovations reshaping the way materials are manufactured and utilized. Among these advancements, dry mix mortar plants have become an essential component in modern construction due to their efficiency, quality, and sustainability. As we look ahead to 2025, several emerging trends and developments are poised to redefine the future of dry mix mortar plants. Let’s explore these trends and understand their implications for the industry.

1. Increasing Demand for Automation

Automation is a driving force behind the future of dry mix mortar plants. Automated systems enhance production efficiency by minimizing human intervention, reducing errors, and ensuring consistent quality. In 2025, we can expect to see more plants adopting advanced robotics and AI-driven systems for tasks like material mixing, weighing, and packaging. These automated processes will lead to improved productivity and cost savings for manufacturers.

Additionally, automation enables real-time monitoring and predictive maintenance, ensuring that the equipment operates at optimal performance. This minimizes downtime and extends the lifespan of machinery, making automation a crucial trend to watch.

2. Focus on Sustainable Practices

Sustainability is a pressing concern across all industries, and dry mix mortar manufacturers are no exception. The production of dry mix mortars involves the use of natural resources, and manufacturers are increasingly adopting eco-friendly practices to reduce their environmental impact. In 2025, we can expect a significant shift towards the use of recycled materials, energy-efficient machinery, and waste management systems.

Moreover, there will be a growing emphasis on producing low-carbon mortars that align with green building standards. The integration of renewable energy sources, such as solar and wind power, in plant operations will further enhance the sustainability of dry mix mortar production.

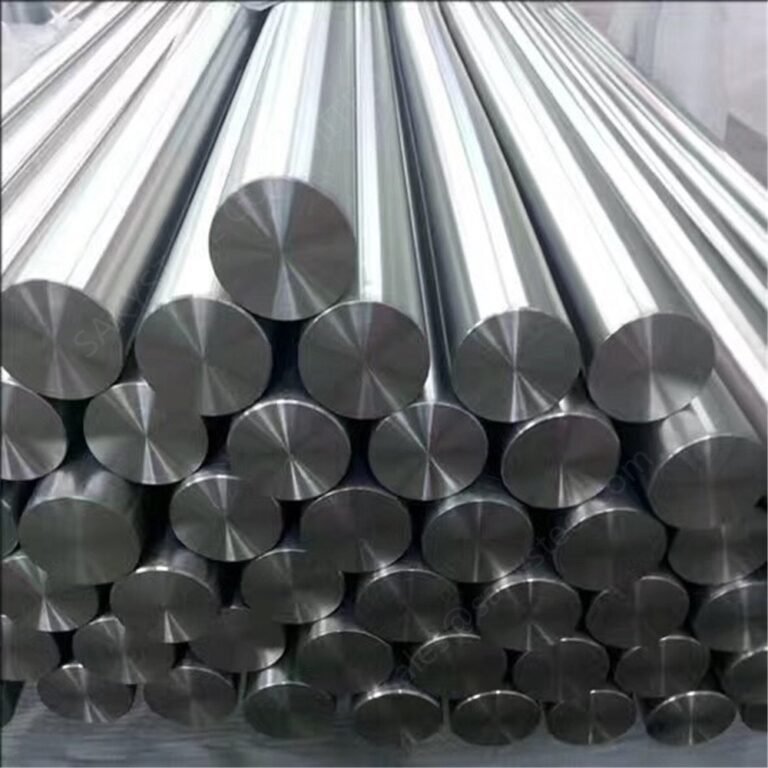

3. Development of Specialized Mortars

The construction industry is witnessing a surge in demand for specialized mortars tailored to specific applications. Dry mix mortar plants are expected to focus on developing products that meet unique requirements, such as:

- Self-leveling mortars for smoother finishes.

- Thermal insulation mortars for energy-efficient buildings.

- Waterproofing mortars for enhanced durability.

By diversifying their product portfolios, manufacturers can cater to the evolving needs of the construction sector, ensuring long-term growth and profitability.

4. Integration of Smart Technologies

Smart technologies are revolutionizing the way dry mix mortar machines operate. In 2025, the adoption of Internet of Things (IoT) devices and data analytics will become more prevalent. These technologies enable real-time monitoring of production processes, providing valuable insights into performance metrics and potential areas for improvement.

For instance, IoT sensors can track raw material levels, temperature, and humidity to ensure optimal mixing conditions. Advanced analytics can help predict demand trends, allowing manufacturers to adjust production schedules accordingly. Such innovations will enhance efficiency, reduce waste, and improve overall plant operations.

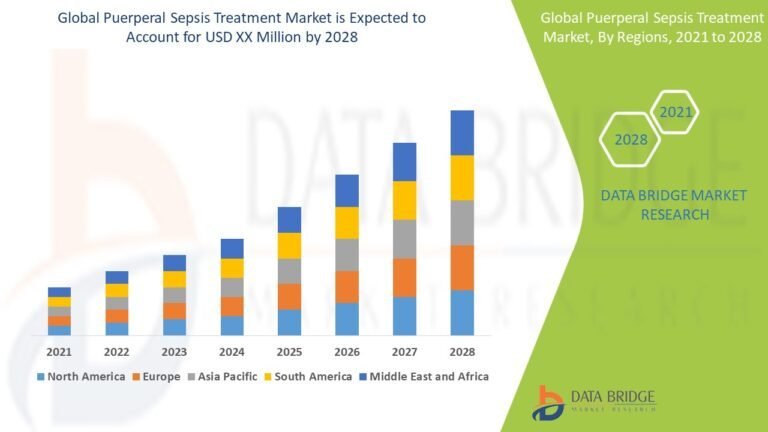

5. Expansion in Emerging Markets

As urbanization continues to accelerate in emerging economies, the demand for dry mix mortars is expected to rise significantly. Countries in Asia, Africa, and South America are investing heavily in infrastructure development, creating lucrative opportunities for dry mix mortar plant manufacturers.

In 2025, we are likely to see an increase in the establishment of dry mix mortar suppliers in these regions. Manufacturers will need to adapt their strategies to cater to local market needs, such as offering cost-effective solutions and providing training programs for workers.

6. Emphasis on Energy Efficiency

Energy efficiency is a critical factor in the operation of dry mix mortar plants. In response to rising energy costs and environmental concerns, manufacturers are prioritizing energy-efficient equipment and processes. Technologies such as heat recovery systems, optimized material flow designs, and energy-efficient mixers are gaining traction.

By adopting these advancements, dry mix mortar plants can reduce their energy consumption and operational costs, contributing to a more sustainable future for the industry.

7. Advancements in Packaging Solutions

Packaging plays a vital role in preserving the quality of dry mix mortars and ensuring their ease of use. In 2025, we can expect innovations in packaging solutions, such as biodegradable bags and smart packaging with QR codes for tracking and product information. These developments will enhance convenience for end-users while addressing environmental concerns.

8. Collaboration and Standardization

Collaboration among industry stakeholders, including manufacturers, researchers, and construction companies, will be crucial in driving innovation in dry mix mortar plants. Efforts to establish standardized practices and certifications will ensure consistency and quality across the industry. This will also build trust among consumers and promote the adoption of dry mix mortars in diverse construction applications.

Conclusion

The future of dry mix mortar plants is marked by exciting advancements and opportunities. From automation and sustainability to specialized products and smart technologies, these trends are reshaping the industry landscape. As manufacturers embrace these changes, they will not only enhance their competitiveness but also contribute to a more efficient and eco-friendly construction sector.

By staying ahead of these trends, companies like Buildmate are leading the way in revolutionizing dry mix mortar production. Their commitment to innovation and quality ensures that they remain at the forefront of the industry, delivering solutions that meet the demands of modern construction.

For anyone looking to invest in Dry Mix Mortar Plants, partnering with a trusted name like Buildmate guarantees reliability, efficiency, and a sustainable future.