As the industries expand and the population increases, the challenge of protecting the environment is intensified from waste and pollution. In this global experiment, polyethylene has with a high degree (HDPE) emerged as a geomembrane inevitable tools, providing strong and long -term solutions for different environmental control and security applications. Their unique characteristics create content for projects seeking imperatives, durability and chemical resistance to protect our natural resources for their future generations.

The Impermeable Shield: What is HDPE Geomembrane?

An HDPE geomembrane sheet is really a synthetic lining designed with high density polyethylene, a thermoplastic polymer is known for its extraordinary power and density ratio. These sheets are designed to create an impenetrable barrier to fluids, gases and dangerous substances. Unlike natural ground lines, which may be exposed to cracks or dislocation, HDPE Giomambrance provides a coherent and reliable barrier, making them ideal for important environmental applications. Their production process often involves a co-dotted method, which ensures uniform thickness and material integrity through the sheet. The inclusion of carbon black in materialization increases the UV resistance significantly, which causes them to meet long -lasting contact for sunlight without deterioration. This flexibility is important for applications where geomembrane can be partially or completely exposed to elements.

A Versatile Guardian: Applications in Environmental Protection

Applications of HDPE geomembrane are different and are important in many fields for environmental protection. Perhaps most especially they are largely used as a landfill liner. Here they primarily create control layers on the base and edges of the landfill, which are known for the toxic fluid as a lie and prevent the underlying soil and groundwater from polluting. They also act as a roof for closed landfills, prevent infiltration of rainwater and control of gas emissions.

In the mining industry, HDPE Giomambrance is important for leaching pillows and tailor -made ponds. Stacking Laich -Pads, used to extract minerals, use these lines to include chemical solutions, to prevent them from escaping into the environment. Tailing ponds, which store waste materials from mining operations, depend on HDPE links to prevent the spread of dangerous mud.

In addition to waste management, these geomembrane waste plays an important role in the water treatment functions. They settle ponds, lagoon and aeration pools, and ensure that the contaminated water is not in the surrounding ecosystem. Similarly, in aquaculture and agriculture, they are served as a dam lining for fishing fields and irrigation reservoirs, preventing water loss through diving and maintaining water quality. Their use in these areas not only saves valuable water resources, but also protects aquatic life and agricultural products from contributors. In addition, HDPE geomembrane is used quickly in environmental therapeutic projects, where they are insulated and include contaminated soil or groundwater, which facilitates cleaning and restoration of contaminated places.

The Edge of Excellence: Key Benefits of HDPE Geomembranes

The broad adoption of HDPE geomembranes is a will for their better performance properties. Their imperative is crucial and ensures zero leakage of liquid and gases, which is the cornerstone of effective control. This property is important to prevent groundwater and soil pollution. They demonstrate exceptional chemical resistance, and strongly stand against a wide range of acids, alkaline, solvents and other aggressive chemicals usually found in industrial waste and contaminated places. This also makes them a durable barrier in the rigid chemical environment.

Stability and long life have underlying properties of HDPE. These HDPE geomembrane price in India are very resistant to puncture, tears and friction, which suitable for demanding conditions and long -term projects. When properly installed and preserved, they may have a lifetime that extends for decades, which can reduce frequent replacements and related costs. Their UV resistance, as mentioned, ensures that they do not have low under sunlight, a common challenge for many other materials. In addition, the flexibility of the HDPE gears allows them to simplify the installation and ensure extensive coverage, similar to irregular areas and challenging places. Finally, HDPE’s weldability is a significant advantage. Larger sheets can be merged at the same time on the site, which creates strong, continuous and leak -proof seams, which are important for the integrity of the container system.

Economic and Strategic Considerations: HDPE Geomembrane Price and Manufacturers

When considering the implementation of HDPE Giomambren solutions, HDPE Giomambren value in India is an important factor. Prices can vary considerably based on thickness, surface treatment (smooth or texture), volume and specific project requirements. Usually, these geomambras are available in different thicknesses, usually from 0.5 mm to 3.0 mm, naturally increases the cost per square meter or kilograms of thick sheets. Competitive landscape in India, with many HDPE Giomambren producers, ensures several alternatives for buyers. Factors that affect the value are also included in transport costs, installation complexity and any custom specifications. It is recommended for buyers to receive offers from several reputable suppliers to ensure competitive prices and product quality.

HDPE established in India is the increasing number of geomembrane manufacturers completing both national and international markets. These manufacturers often follow international quality standards, for example determined by the Geocynthetic Institute (GSI), and ensure the reliability and performance of their products. Eminent manufacturers provide detailed product specifications, quality control documents and often provide technical support for project planning and installation. The choice of a manufacturer with a proven tracking list and strong quality assurance protocol is important for success and long -term integrity of any environmental protection project.

Conclusion

The HDPE geomembrane manufacturers represents a foundation stone in modern environmental technology and protection. Their inherently imperviousness, remarkable durability and chemical resistance make them unique to involving dangerous substances, preventing pollution and conservation of significant resources. From the protection of groundwater in landfills to adaptation of water management in agriculture, these synthetic lining provides strong and cost -effective solutions. As -Global environmental considerations continue to assemble, the role of HDPE Geomambrain in a permanent future building will only expand, and strengthen its position as an inevitable tool for a healthy planet.

Frequently Asked Questions (FAQ)

Question: What is the specific life of HDPE Geomambraine in buried applications?

A: When properly installed and underground is buried, served UV with radiation and ups and downs in extreme temperature, an HDPE -geomambrain can be an impressive life, often from 50 to 100 years or more, based on specific soil conditions, chemical risk and total website stability. It contributes significantly to these conditions to a decline in the underlying resistance of HDPE.

Question: Can HDPE geomembrane be repaired when HDPE is damaged during installation or operation?

A: Yes, HDPE geomembranes are heavily repaired. Smaller punctures or tears that may occur during installation or even during operating life to a function can usually be repaired using special welding techniques, such as warm road welding or extrusion welding. These repairs, performed by certified technicians, create strong, permanent bonds that restore the feed’s integrity and ensure continuous control.

Question: What are specific environmental conditions that can limit the efficiency of HDPE gemburans?

A: Although extremely strong, extreme environmental conditions can withstand challenges. For example, long -term maintenance can affect the properties of much more temperature materials, although HDPE is designed to meet a wide temperature range. Similarly, places with significant seismic activity or very unstable undergrading may require additional engineering ideas to prevent excessive stress or demolition of geomembrane. Proper evaluation and design are important for addressing such factors.

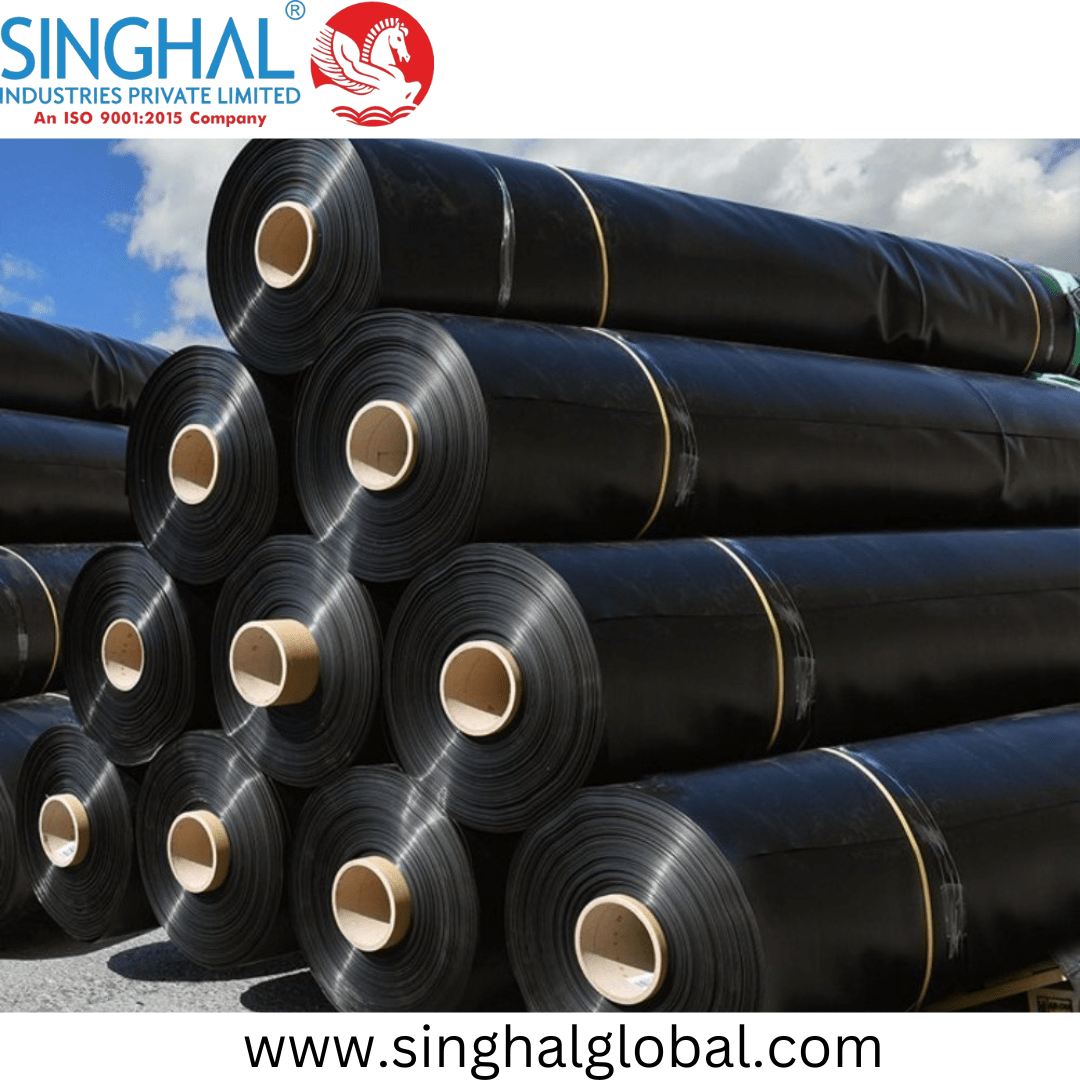

Question: Who is the largest manufacturer of HDPE Geomembrane?

A: Singhal Industries Private Limited is a prominent manufacturer and supplier of HDPE Geomembrane sheets and pond liners, serving both the Indian and international markets with a focus on quality and diverse applications.