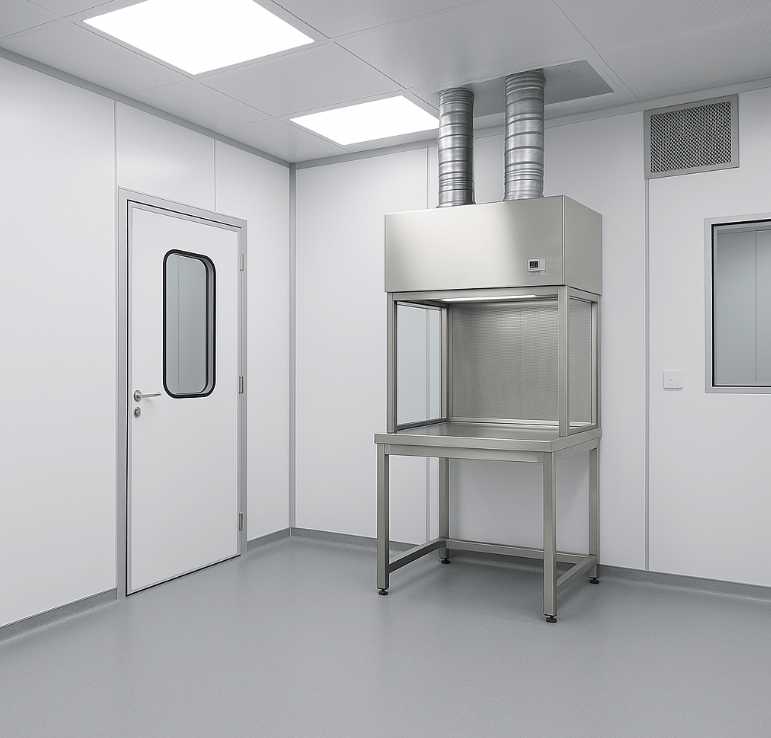

When you think about a cleanroom, what comes to mind first? Most people picture high-tech machines, biosafety cabinets, or powerful HEPA filters. While these are essential, there’s one element often overlooked the walls. Clean room wall panels are not just partitions; they are the backbone of contamination control, forming the foundation of sterile environments in industries like pharmaceuticals, biotechnology, healthcare, and electronics.

This article explains why clean room wall panels matter, what materials are commonly used, best practices for installation, and why choosing the right supplier is vital for long-term performance and compliance.

What Makes Clean Rooms Special?

A cleanroom is a specially designed space where air quality, temperature, humidity, and airborne particle levels are tightly controlled. They are essential in industries where even a speck of dust or a slight contamination can ruin products worth millions or risk patient safety.

For example:

- In pharmaceuticals, a contaminated environment could spoil an entire drug batch.

- In electronics, static or dust particles can damage delicate microchips.

- In biotechnology, contamination can compromise research results or expose staff to harmful substances.

In each of these cases, the cleanroom walls form the first and most consistent line of defense against contamination.

Why Clean Room Wall Panels Matter

The walls of a cleanroom do far more than divide spaces. They:

- Maintain airtightness: Clean room wall panels prevent air leakage, ensuring that the controlled environment remains stable.

- Support hygiene: Panels are designed to resist microbial growth and withstand repeated cleaning with strong disinfectants.

- Enable modularity: Many panels are modular, meaning they can be installed, dismantled, or upgraded quickly without rebuilding the entire room.

- Enhance safety: High-quality panels meet fire resistance and anti-static requirements, keeping both staff and products safe.

Without the right panels, even the most advanced cleanroom systems can fail compliance audits or risk contamination.

Types of Materials Used in Clean Room Wall Panels

Not all panels are created equal. The choice of material impacts the durability, compliance, and overall performance of a cleanroom. Here are the most widely used options:

1. Sandwich Panels

These are the most popular type of clean room wall panels. They consist of two outer sheets (steel, aluminum, or laminate) with an insulating core material in between.

- PUF (Polyurethane Foam) – Lightweight, durable, and offers good thermal insulation.

- PIR (Polyisocyanurate) – Similar to PUF but with better fire resistance.

- Rockwool – Provides excellent fire and sound insulation, often used in pharma applications.

2. Stainless Steel Panels

These are preferred in highly sterile environments, such as biotechnology labs or vaccine production units. Stainless steel is corrosion-resistant, strong, and easy to clean.

3. Aluminum Honeycomb Panels

Known for being lightweight yet rigid, these panels are often used where stability and strength are crucial.

4. High-Pressure Laminates (HPL)

Durable and cost-effective, HPL panels are suitable for less critical cleanroom zones. They are scratch-resistant and easy to maintain.

Best Practices for Installing Clean Room Wall Panels

Even the best materials won’t perform if they’re not installed correctly. Here are some installation best practices:

1. Ensure Airtightness

Sealed joints are critical to prevent air leakage. Panels should fit flush with ceilings and flooring systems to avoid dust accumulation.

2. Go Modular

Modular clean room wall panels allow easy dismantling and reinstallation, which is cost-effective for facilities that expand or upgrade frequently.

3. Prioritize Cleanability

Smooth, seamless surfaces make cleaning easy and effective. Panels should withstand frequent disinfection with strong chemicals.

4. Plan Accessories Early

Pass boxes, view panels, and electrical fittings should be integrated during the installation phase, not as afterthoughts. Cutting into panels later can compromise airtightness.

5. Use Certified Installers

Improper installation can cause compliance failures. Working with certified cleanroom installers ensures panels meet ISO 14644 and GMP standards.

Compliance and Standards

Cleanroom wall panels aren’t just about construction – they’re about compliance. In India, panels must align with global and local standards such as:

- ISO 14644 for cleanroom classification.

- GMP (Good Manufacturing Practices) for pharmaceutical and biotech industries.

- Fire safety standards under local regulations.

Auditors often check not only the equipment but also the quality of wall panel installation. Poor documentation or non-compliant materials can lead to costly rejections.

Benefits of Choosing the Right Clean Room Wall Panels

- Regulatory compliance – Panels that meet ISO and GMP standards reduce the risk of failed inspections.

- Cost savings – Durable materials lower long-term maintenance costs.

- Flexibility – Modular systems make expansions or upgrades easier.

- Safety and hygiene – Fire-resistant, antimicrobial panels improve both product and worker safety.

- Operational efficiency – Panels that integrate seamlessly with cleanroom systems enhance workflow.

Choosing the Right Supplier

While many companies offer partitions and panels, not all have cleanroom expertise. When choosing a supplier, look for:

- Industry experience – Providers with proven work in pharma, biotech, or electronics cleanrooms.

- Customization – Ability to deliver panels in different sizes, thicknesses, and finishes.

- Validation support – Assistance with ISO and GMP compliance.

- After-sales service – Maintenance, replacement, and support for long-term performance.

Trusted suppliers like Ultrafil specialize in clean room wall panels that meet international standards while catering to the specific needs of Indian industries.

Common Mistakes to Avoid

- Using non-cleanroom-grade materials like wood or painted drywall.

- Ignoring sealing quality, which leads to leaks and contamination.

- Skipping modular options, making future upgrades more expensive.

- Working with general contractors instead of specialized cleanroom experts.

Final Thoughts

Clean room wall panels may not be the flashiest part of a cleanroom, but they are the backbone of contamination control. From maintaining airtightness to ensuring compliance with ISO and GMP standards, the right panels create a strong foundation for cleanroom success.

By investing in high-quality clean room wall panels and working with experienced suppliers, industries can protect their products, staff, and reputation. For Indian businesses in pharmaceuticals, biotech, and electronics, choosing a trusted partner like Ultrafil ensures cleanrooms that perform reliably, pass audits, and support growth.