Construction sites are inherently hazardous environments. The nature of the work—heavy machinery, elevated structures, and dynamic working conditions—means that safety must be a top priority at all times. Despite rigorous protocols, procedures, and technological advancements, one critical factor continues to pose a significant threat to construction site safety: human error.

Understanding Human Error

Human error refers to mistakes or lapses in judgment made by workers, supervisors, or anyone involved in the construction process. These errors can arise from fatigue, miscommunication, inexperience, inadequate training, or even complacency. Unlike mechanical failures or environmental hazards, human errors are more unpredictable and, in many cases, preventable with the right interventions.

Human error can be categorized into several types:

- Slips and lapses – Often unintentional and resulting from attention deficits or memory failure.

- Mistakes – Occur when individuals have incorrect knowledge or apply rules inappropriately.

- Violations – Deliberate deviations from established safety procedures or protocols.

Each type of error can lead to severe consequences on construction sites, including injury, equipment damage, project delays, or even fatalities.

The Consequences of Human Error

The statistics surrounding construction site accidents are telling. According to the Health and Safety Executive (HSE), human error is a leading cause of accidents in the UK construction industry. Errors such as misjudging distances, neglecting to secure harnesses, or failing to properly lock machinery contribute to falls, electrocutions, and equipment-related injuries.

Beyond the physical and emotional cost to workers and their families, accidents driven by human error also carry significant financial consequences. These include medical expenses, compensation claims, project downtime, insurance premium increases, and reputational damage.

Common Causes of Human Error in Construction

Several key factors contribute to the prevalence of human error on construction sites:

- Fatigue and Long Hours

Workers often operate in demanding conditions for extended periods. Physical exhaustion impairs judgment, coordination, and concentration, leading to higher chances of accidents. - Inadequate Training

In many cases, workers may lack the proper training or understanding of safety protocols and machinery. Without adequate knowledge, they may unintentionally misuse equipment or ignore safety procedures. - Poor Communication

Misunderstandings between team members or departments can lead to serious oversights. For example, a failure to communicate a change in site conditions could result in workers entering unsafe areas. - Complacency and Overconfidence

Workers who have spent years on sites without incident may develop a false sense of security. This can lead to skipping essential safety steps or ignoring minor hazards. - Distractions and Multitasking

Trying to manage multiple tasks at once or becoming distracted—by mobile phones or other site activity—can result in critical mistakes.

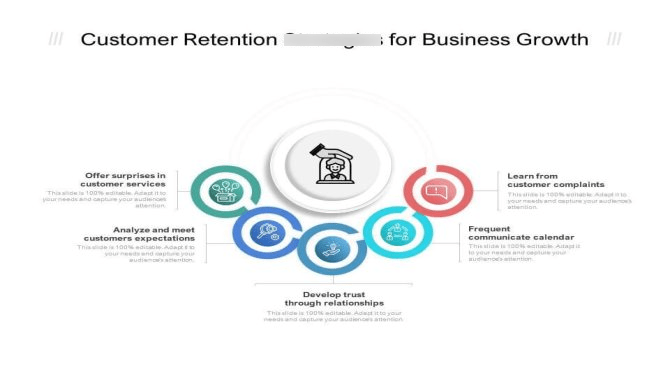

Preventing Human Error

Reducing human error on construction sites involves a combination of culture, training, technology, and enforcement. Here are some strategies:

- Comprehensive Training Programs

Training must go beyond box-ticking exercises. Workers should receive hands-on, scenario-based training that prepares them for real-world challenges. - Effective Communication Systems

Daily briefings, clear signage, and open communication channels can help ensure everyone is aware of site changes, potential hazards, and procedural updates. - Fatigue Management

Rotating shifts, enforcing breaks, and monitoring worker hours are crucial for ensuring workers remain alert and responsive throughout their shifts. - Encouraging a Safety Culture

Leadership must demonstrate that safety is a priority. This includes empowering workers to report concerns without fear of reprisal and rewarding proactive safety behavior. - Utilizing Technology

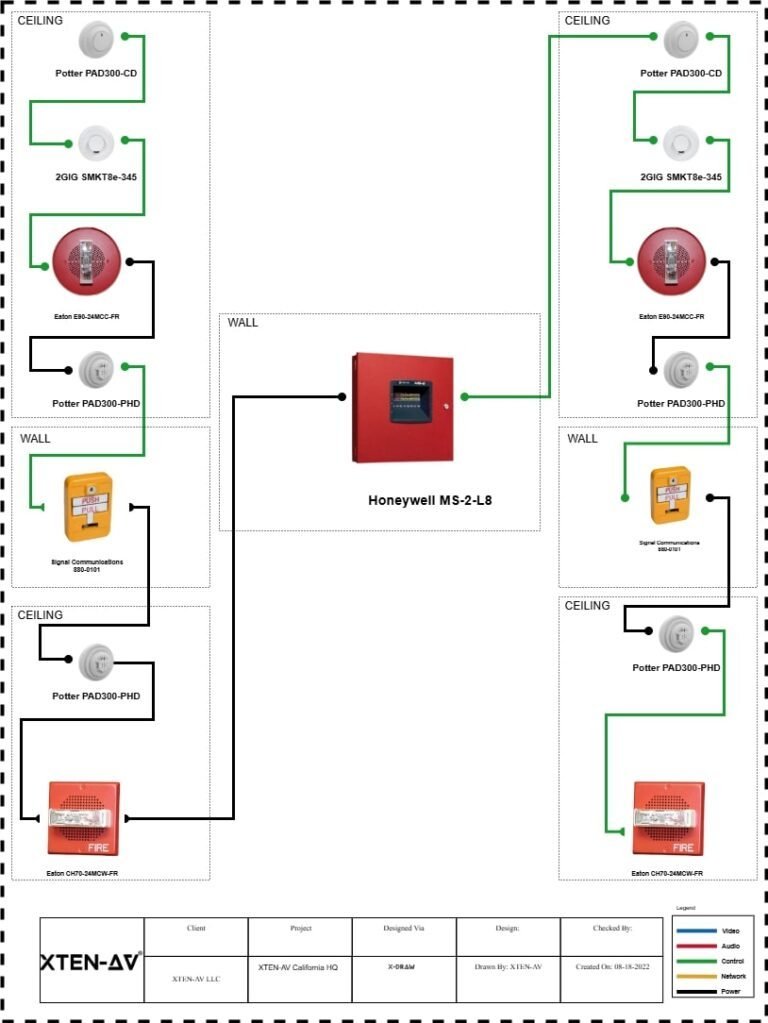

Wearable devices that monitor fatigue, digital checklists, and real-time hazard detection tools can assist in reducing the burden on human attention and memory.

Regional Commitment to Health and Safety

Regions like Hampshire and Hertfordshire have shown proactive approaches in implementing robust health and safety practices. Local authorities and construction firms are placing increasing importance on reducing accidents caused by human error through continuous training and safety audits.

The presence of regulatory services and consultancies supporting Health and Safety Hampshire and Health and Safety Hertfordshire indicates a growing regional commitment to improving standards across construction sites. These areas are investing in awareness campaigns, inspection programs, and collaboration with businesses to foster safer working environments.

Conclusion

Human error is an unavoidable reality of any industry involving manual labor and complex processes—but it doesn’t have to result in disaster. By understanding the types and causes of human error, construction companies can take decisive steps to minimize risk and improve safety outcomes.

Prevention requires more than just policies; it demands a cultural shift where safety is ingrained into every task, decision, and interaction on-site. With the right combination of education, communication, oversight, and technology, the construction industry can significantly reduce the impact of human error and ensure a safer future for all workers.