The starter motor might be one of the smallest components in a vehicle’s engine system, but its role is massive. Without it, your car simply wouldn’t start. From cranking cold engines to igniting combustion, the starter motor is what gets everything moving literally.

What is a Starter Motor?

A starter motor is an electric motor that initiates the internal combustion process in an engine. It does this by turning the engine’s flywheel, which starts the crankshaft rotating and enables the engine to begin its operation under fuel power.

In most modern vehicles, the starter motor is powered by the car’s battery and activated via the ignition switch. Once the engine begins running on its own, the starter motor disengages.

How Does a Starter Motor Work?

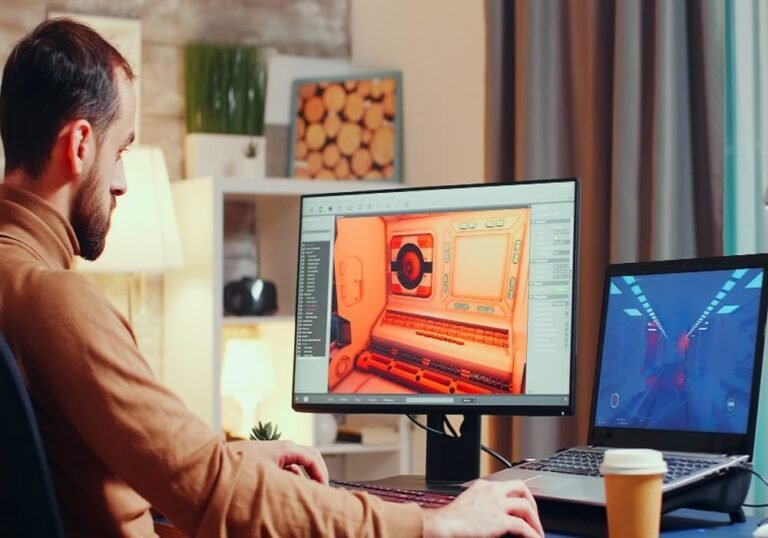

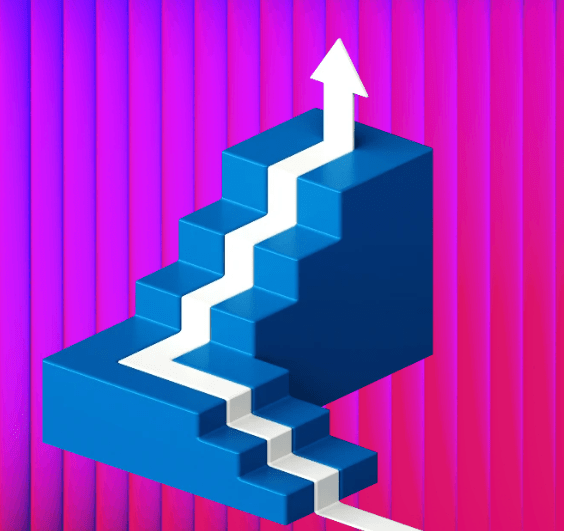

Here’s a step-by-step breakdown of how a typical starter motor functions:

Ignition Activation: When the driver turns the key or presses the start button, current flows from the battery to the starter motor.

Solenoid Engagement: The starter solenoid pushes the starter gear (also called a pinion) to engage with the engine’s flywheel.

Cranking the Engine: The electric motor spins the pinion gear, which turns the flywheel and cranks the engine.

Disengagement: Once the engine starts running on its own, the solenoid retracts the pinion gear, and the motor stops.

Key Components of a Starter Motor

Armature: The rotating part inside the motor.

Commutator: Transfers current to the armature windings.

Brushes: Maintain contact with the commutator.

Field Coils or Permanent Magnets: Create the magnetic field required for motor operation.

Solenoid: Acts as a switch and mechanical actuator.

Drive Gear (Bendix gear): Engages with the engine flywheel.

Types of Starter Motors

1. Conventional Electric Starter

The most common type, using a motor and solenoid to start internal combustion engines.

2. Gear Reduction Starter

Uses a set of gears to reduce motor speed and increase torque — ideal for larger engines or heavy-duty applications.

3. Inertia Starter

An older design where the pinion gear spins into engagement using inertia alone.

4. Start-Stop System Starters

Used in modern fuel-efficient cars, designed for frequent engine starts without excessive wear.

Applications of Starter Motors

While primarily associated with automotive engines, starter motors are used in:

Motorcycles and scooters

Trucks and buses

Boats and marine engines

Generators

Heavy machinery and agricultural equipment

Common Issues with Starter Motors

Over time, starter motors can wear out or develop problems. Common symptoms include:

Clicking sound with no engine turn

Grinding noise (possibly due to a worn pinion or flywheel)

Intermittent starting issues

No response when turning the key

Typical causes include worn brushes, faulty solenoids, battery issues, or bad wiring connections.

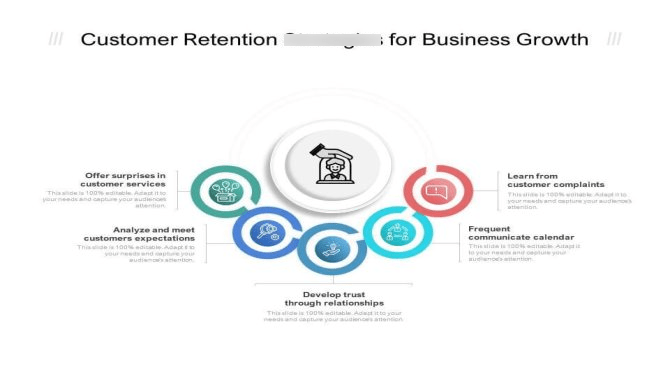

Maintenance and Tips

Keep battery terminals clean and tightly connected.

Ensure the battery is healthy; low voltage can harm the starter.

Listen for abnormal sounds — grinding or clicking may indicate issues with the starter or flywheel.

You can avoid prolonged cranking; repeated short attempts are better.

Evolution of Starter Motors in Modern Vehicles

Modern cars with start-stop systems or hybrid technology require advanced starter motors that are faster, more durable, and capable of frequent use. Some newer vehicles even combine the alternator and starter into an Integrated Starter-Generator (ISG) system.

Environmental Impact and Efficiency

Starter motors contribute to better fuel efficiency in systems like automatic start-stop, which shuts down the engine during idling (e.g., at traffic lights). This helps reduce fuel consumption and lower emissions, especially in urban driving.

Diagnosing Starter Motor vs. Battery Problems

Many people confuse starter issues with a dead battery. A quick test: if your lights and electronics work but the engine doesn’t crank (or just clicks), the starter motor is likely the issue, not the battery.

The Role of the Starter Relay and Solenoid

The starter solenoid acts as a powerful switch, directing high current to the motor. A failing solenoid or relay can mimic motor failure, so it’s important to test these components during troubleshooting.

Starter Motor Maintenance: Is It Necessary?

While starter motors are generally low-maintenance, periodic inspection of wiring, terminals, and grounding points helps prevent premature failure. In commercial or off-road vehicles, preventive maintenance is especially valuable.

Rebuilt vs. New Starter Motors: Which Should You Choose?

Rebuilt (remanufactured) starters are cost-effective and eco-friendly, but quality can vary. For critical applications or long-term reliability, investing in a new OEM or high-quality aftermarket unit is often the better choice.

Signs It’s Time to Replace Your Starter Motor

Key indicators include:

Slow engine cranking

Smoke or a burning smell near the engine bay

The starter is engaging, but not turning the engine on

Frequent need to jump-start despite a healthy battery

Final Thoughts

The starter motor may only operate for a few seconds each time you drive, but without it, your journey can’t even begin. As vehicles evolve toward hybrid and electric systems, the role of traditional starter motors is also changing, being replaced or integrated with more advanced systems. Still, in conventional combustion engines, the starter motor remains a vital piece of the automotive puzzle.