The semiconductor industry in the United States is at an important point. By 2025, it is expected to grow a lot because of new technology, support from the government, and high demand for chips in many areas. But this growth also brings some problems, like weaknesses in supply chains, not enough skilled workers, and international issues. In this blog, we will look at the trends affecting chip manufacturing in America, explain how semiconductors are made, and talk about the chances and challenges ahead. This overview aims to provide helpful information and inspire people involved in the semiconductor industry.

The Growth of the Semiconductor Manufacturing Industry in the USA

The semiconductor manufacturing industry in the United States is growing significantly, thanks to a law called the CHIPS and Science Act, which was passed in 2022. This law provides $52.7 billion to help increase domestic chip production. Out of this money, $39 billion is for manufacturing support and $13.7 billion is for research and development. The Semiconductor Industry Association (SIA) says that by 2032, the U.S. is likely to triple its ability to make semiconductors, with a growth rate of 203%. This will raise the U.S. share of the world’s chip production from 10% in 2022 to 28% by 2032, a big increase compared to the 9% it would have been without this law.

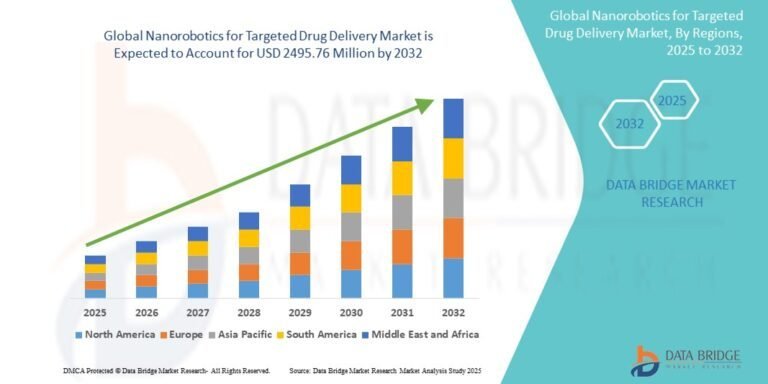

In 2024, the global semiconductor manufacturing industry was worth about $681 billion. It is expected to grow to $755 billion in 2025 and reach over $2 trillion by 2032. This means it will grow at a rate of about 15.4% each year. The U.S. market alone is projected to be $258 billion by 2032. This growth is fueled by the demand for electronics, making chips, and new technologies like artificial intelligence (AI) and the Internet of Things (IoT).

This growth is not just about how many chips are made; it’s also very important for our strategy. Semiconductors are essential for today’s technology. They power smartphones, data centers, electric cars, and advanced defense systems. The U.S. wants to be a leader in making chips again. This will help reduce dependence on other countries and improve national security.

Key Drivers of Growth

- AI and High-Performance Computing Demand: The growth of AI and high-performance computing is mainly due to the increased need for advanced chips. These chips, like high-bandwidth memory (HBM) and AI accelerators, will help the semiconductor market grow a lot by 2030. For example, demand for memory chips is expected to jump by over 24% in 2025 because more people will use HBM3 and HBM3e for AI tasks.

- Government Incentives: Government support, like the CHIPS Act, has led to more than 90 new manufacturing projects in 28 states, with around $450 billion in private investments announced. These projects are set to create 56,000 new direct jobs and support many more indirect jobs, which will help the U.S. economy.

- Automotive and IoT Expansion: In the automotive industry, there is a larger need for semiconductors, especially for electric vehicles (EVs) and self-driving cars. There is high demand for chips using older technologies (over 28nm), and the move towards hybrid vehicles is making more chips available for other uses. Additionally, Internet of Things (IoT) devices need chips that are low-power and can connect easily, further increasing demand.

The Semiconductor Production Process: A Complex Journey

To understand the changes in the semiconductor manufacturing industry, it’s important to know how semiconductors are made. This process has several steps, and each step needs careful work, advanced tools, and a strong supply chain for semiconductors.

- Design and Development: The process starts with designing computer chips. Engineers use special tools to make plans for building these chips. Companies like NVIDIA and Qualcomm only focus on design and hire other companies, called foundries, like TSMC, to actually make the chips.

- Wafer Fabrication: Silicon wafers are thin slices of silicon used to make computer chips. They are made in special clean rooms. First, light is used to shine patterns onto the wafers. Next, unwanted parts are removed. Then, some materials, like boron or phosphorus, are added to change how well the wafer conducts electricity. This process needs expensive machines and very pure materials.

- Assembly, Testing, and Packaging (ATP): After making the wafers, they are sliced into separate chips. These chips are then tested to make sure they work and are packaged to be used in devices. New packaging methods, such as TSMC’s Chip-on-Wafer-on-Substrate (CoWoS), are very important for AI chips. The ability to produce these chips is expected to double, going from 330,000 wafers in 2024 to 660,000 in 2025.

- Quality Control and Distribution: Thorough testing makes sure that chips work well before they are sent to companies that make electronics, car systems, or data centers.

Making semiconductors takes a long time, usually four to six months. It has more than 500 different steps. This complicated process shows how important it is to have a strong supply chain for semiconductors, which includes materials, tools, and shipping around the world.

Challenges Facing the Semiconductor Manufacturing Industry

The semiconductor manufacturing industry has a bright future, but it also has big problems that could stop it from growing if not fixed. Here are the main challenges and some possible ways to solve them:

1. Talent Shortages

The industry is having a serious problem finding skilled workers. A study says that by 2030, the U.S. will need 67,000 more technicians, computer scientists, and engineers. Overall, the economy will need 1.4 million more workers in science, technology, engineering, and math (STEM) fields. Around the world, one million additional workers will also be needed by 2030.

To solve these problems, we can:

- Train Workers: Work with schools and colleges to teach important skills for the semiconductor industry. For example, companies like TSMC are bringing skilled workers from Taiwan to the U.S. while also training local workers.

- Diverse Workers: Reach out to different groups of people, like women and older adults. Offering flexible work hours and training programs can help attract them. Making jobs more appealing through better career options and inclusive workplaces is important.

- Support STEM Education: Put more money into education for STEM subjects to prepare future engineers and technicians. Programs from the CHIPS Act help with this effort.

2. Supply Chain Vulnerabilities

The semiconductor supply chain is spread across the world, relying on key materials like neon gas from Ukraine, tantalum, and silicon mainly from Africa and China. This can cause problems when there are international conflicts, natural disasters, or shipping delays. For example, Taiwan’s drought in 2023 affected the water needed to clean semiconductor wafers.

To solve these issues:

- Diversification: Invest in local supply chains or work with friendly countries to avoid relying too much on one area.

- Recycling: Increase recycling of electronic waste to recover rare materials, which helps when there are export limits from China.

- Advanced Analytics: Use big data and Internet of Things technology to keep track of the supply chain in real-time. Companies like JUSDA have cut waiting times by 20% using their JusLink platform.

3. Geopolitical Tensions and Trade Policies

The trade problems between the U.S. and China, along with rules on advanced computer chips, are making it hard to get these chips. New taxes planned by the U.S. government for 2025 could make things more expensive and affect global trade. China’s limits on certain materials like gallium and germanium also create more issues.

Possible solutions include:

- Working with allies: The U.S. should make strong trade agreements with friends to ensure access to global markets and materials. The U.S. should also try to sell its chips in other countries.

- Changing policies: The U.S. should expand support programs for chip production, like tax breaks, to stay competitive. It’s important to support stable trade rules to reduce the impact of new taxes.

- Planning for challenges: Companies should keep extra supplies and use different suppliers to protect themselves from trade problems, as experts recommend.

4. High Capital and Operating Costs

Building new factories for making chips costs a lot of money, with global spending expected to be $2.3 trillion from 2024 to 2032. Running these factories is also getting more expensive because of high energy use and the need for better tools. Here are some solutions:

- Government Support: Keep the funding program from the CHIPS Act for advanced manufacturing going after 2026 to help with costs.

- Energy Efficiency: Put money into green technologies, like chips that turn wasted heat into electricity, to lower running costs.

- Chiplet Designs: Use chiplet designs to make production cheaper and more flexible, as they let different parts be put together easily.

The Future of Chip Manufacturing in America

The semiconductor manufacturing industry in the U.S. is set for big growth, driven by new ideas and smart investments. Here are some important trends shaping the future of making chips:

- New Packaging Methods: New techniques like Fan-Out Panel Level Packaging (FOPLP) and TSMC’s CoWoS are becoming popular, especially for AI chips. These methods improve performance and efficiency, and the packaging industry is expected to grow by 9% in 2025.

- Eco-Friendly Efforts: The industry is focusing on green solutions, like making chips in a way that is better for the environment, especially for data centers and electric vehicles. Over 93% of leaders in the semiconductor field believe being sustainable will help make more profit.

- New Technologies: Innovations like quantum computing and edge computing, along with 2nm technology, are changing how chips are made. These new developments will need new ways to produce chips and different materials, leading to more research and development spending.

- Manufacturing Centers: States like Arizona, Texas, and New York are becoming important places for chip manufacturing, thanks to good business policies and infrastructure improvements. For example, TSMC’s factories in Arizona are expected to start making 4nm chips by mid-2025, showing this trend.

Conclusion: Navigating the Road Ahead

The semiconductor industry in the USA is growing rapidly. This growth is fueled by the CHIPS Act, the demand for AI, and smart investments. However, there are challenges such as not having enough skilled workers, problems with supply chains, and uncertainties in international relations. To address these issues, the U.S. should focus on training workers, making supply chains more diverse, supporting stable policies, and using new technologies. This way, the U.S. can become a leader in chip manufacturing worldwide.

People in the semiconductor manufacturing industry need to work together with governments, schools, and businesses to solve problems and take advantage of chances. The future of making computer chips looks good, but it requires being strong, flexible, and willing to create new ideas. As we approach 2025, the U.S. can play a key role in the worldwide semiconductor supply chain, making the world smarter, greener, and more connected.