In the paper manufacturing industry, the production process is critical to ensuring both the efficiency and quality of the end product. A vital but often overlooked aspect of this process is the control of foam and air, which can disrupt production and degrade the quality of paper. This is where Paper Machine Deformer chemicals come into play. These chemicals help manage foam and air entrapment, which are common issues in paper manufacturing. By understanding the importance of Paper Machine Deformer chemicals, manufacturers can improve operational efficiency, reduce downtime, and produce high-quality paper consistently.

What Is a Paper Machine Deformer?

A Paper Machine Deformer is a chemical agent used in the paper production process to control foam and air. During paper production, foam buildup and air entrapment can cause several issues, including uneven texture, poor printability, and reduced paper strength. Paper Machine Deformer chemicals work by breaking down foam and preventing air from becoming trapped in the paper fibers, ensuring smoother production and more consistent quality.

These chemicals are typically added at various stages of the production process, depending on the type of paper being made. They are essential in controlling the formation of foam, which can hinder the smooth flow of materials through the paper machine.

1. Enhancing Paper Quality

One of the most significant benefits of Paper Machine Deformer chemicals is the improvement of paper quality. Foam and air buildup during production can cause imperfections in the paper. These imperfections may include bubbles, weak spots, and irregular texture, which compromise the overall strength and durability of the paper.

By effectively controlling foam and air, Paper Machine Deformer chemicals ensure a smoother, more uniform texture. This leads to stronger and more durable paper. For industries such as printing and packaging, where high-quality paper is essential, the consistency and smoothness achieved through the use of these chemicals enhance the final product’s value.

Furthermore, Paper Machine Deformer chemicals help improve the paper’s printability. A smoother surface allows for more precise ink absorption, resulting in clearer, sharper prints. This is particularly important in the production of high-end products such as fine paper, which requires consistent texture and print quality.

2. Increased Production Efficiency

Efficient production is crucial for paper manufacturers aiming to meet market demand while maintaining quality. Paper Machine Deformer chemicals play a critical role in improving production efficiency by preventing foam and air buildup, which can disrupt the flow of materials through the machine. When foam or air accumulates in the pulp slurry, it can create blockages or uneven flows, slowing down production speeds and increasing waste.

By controlling these disruptions, Paper Machine Deformer chemicals allow for a smoother, faster production process. This results in increased throughput, allowing manufacturers to meet higher demand while reducing waste. In addition to improving production speed, these chemicals also reduce the likelihood of production interruptions, which can cause delays and affect overall efficiency.

3. Reducing Downtime and Maintenance Costs

In any manufacturing operation, downtime can be costly, both in terms of time and money. In the paper production process, foam buildup and air entrapment can cause machines to malfunction, resulting in frequent stops for cleaning or maintenance. This downtime is not only costly but also reduces the overall efficiency of the production line.

By using Paper Machine Deformer chemicals, manufacturers can reduce the frequency of these interruptions. These chemicals help prevent foam and air from building up in the production system, reducing the need for cleaning and maintenance. With fewer disruptions, machines run more smoothly, leading to less wear and tear, fewer breakdowns, and ultimately lower maintenance costs.

This reduction in downtime contributes directly to increased production capacity, allowing manufacturers to operate more efficiently and improve profitability.

4. Cost-Effective Solution

The use of Paper Machine Deformer chemicals is a cost-effective solution for paper manufacturers. By improving operational efficiency, reducing downtime, and enhancing paper quality, these chemicals help manufacturers reduce production costs in the long run. In addition, these chemicals help minimize waste by improving the flow of materials through the machine, which further reduces costs.

Moreover, the high-quality paper produced with the help of Paper Machine Deformer chemicals can be sold at a premium price, increasing profitability. As manufacturers improve their production processes, they can achieve higher output without compromising on quality, ultimately boosting their revenue.

In today’s competitive market, cost-effectiveness is essential for staying ahead of the competition. Investing in Paper Machine Deformer chemicals is a smart move for any paper manufacturer looking to reduce operational costs and increase profitability.

5. Sustainable Paper Manufacturing Practices

Sustainability is an increasingly important concern in the paper industry. Manufacturers are under pressure to reduce their environmental impact while maintaining high-quality production standards. Paper Machine Deformer chemicals contribute to more sustainable manufacturing by reducing waste and improving resource efficiency.

By improving production efficiency and reducing foam and air buildup, these chemicals help minimize the need for excessive raw material consumption. This leads to less waste and lower energy usage, making the overall production process more environmentally friendly.

Additionally, many Paper Machine Deformer chemicals are designed to be biodegradable and non-toxic, making them a safer, more eco-friendly option compared to traditional chemical agents. By adopting Paper Machine Deformer chemicals, paper manufacturers can align their production processes with sustainability goals, contributing to a greener, more responsible industry.

6. Tailored Solutions for Different Paper Types

One of the key advantages of Paper Machine Deformer chemicals is their versatility. Different types of paper, such as fine paper, packaging material, or industrial paper, have different production requirements. Paper Machine Deformer chemicals can be tailored to meet these specific needs, ensuring optimal performance for each type of paper.

For example, Paper Machine Deformer chemicals used in fine paper production may focus on providing a smooth finish and better printability, while those used for packaging materials may focus on enhancing the strength and durability of the paper. This customization ensures that manufacturers can achieve the desired characteristics for each type of paper, without compromising on efficiency.

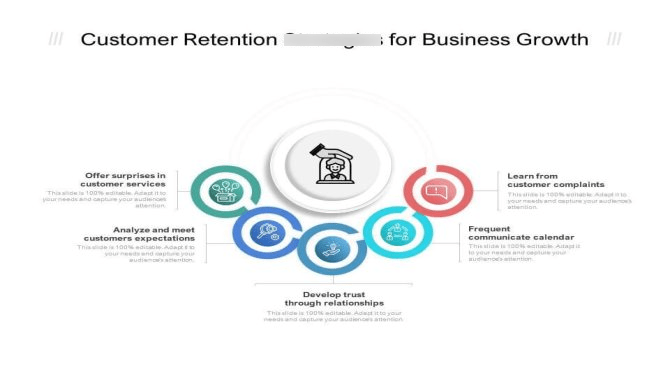

Why Paper Machine Deformer Chemicals Are Essential

Paper Machine Deformer chemicals are an essential part of modern paper manufacturing. By controlling foam and air, they enhance paper quality, increase production efficiency, reduce downtime, and provide a cost-effective solution for paper manufacturers. These chemicals also contribute to more sustainable manufacturing practices, making them an ideal choice for eco-conscious manufacturers.

Investing in Paper Machine Deformer chemicals not only improves the production process but also helps manufacturers stay competitive in a rapidly evolving market. Whether you are producing fine paper, packaging materials, or industrial-grade paper, these chemicals are key to improving both quality and efficiency in your operations.